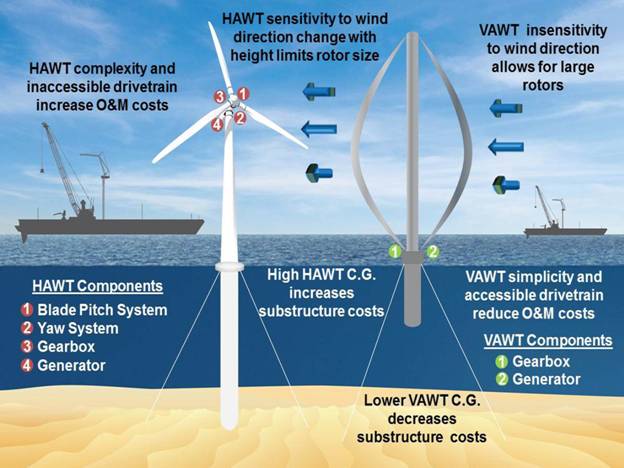

Mention wind machines and most folks think instantly of the large horizontal spinning propeller blade types that dominate the energy news; but wind turbines come in vertical axis types as well and there are some big benefits for using them. Sandia National Laboratories’ wind energy researchers are re-evaluating vertical axis wind turbines (VAWTs) to help solve some of the problems of generating energy from offshore breezes. The five-year, $4.1 million project began in January of 2012; and draws heavily on Sandia’s rich history with VAWT design and testing, going back to the 1970s and 80s.

VAWTs offer three big advantages that could reduce the cost of wind energy: a lower turbine center of gravity; reduced machine complexity; and better scalability to very large sizes. Having their drive-train more compact and lower to the water means a more stable machine and one easier and faster to maintain; and this design has fewer parts, not requiring a control system to orient toward the blowing wind. VAWTs are omni-directional. These characteristics fit the design constraints for offshore wind: the high cost of support structures; the need for simple, reliable designs; and economic scales that demand larger machines than current land-based designs.

Wind speeds are typically greater and more frequent offshore than on land, so locating them there makes good sense. According to experts at Sandia, large offshore VAWT blades in excess of 300 meters will cost more to produce than blades for onshore wind turbines. But as the machines and their foundations get bigger—closer to the 10–20 megawatt (MW) scale—turbines and rotors become a much smaller percentage of the overall system cost for offshore turbines, so other benefits of the VAWT architecture could more than offset the increased rotor cost.

Another engineering challenge will be the aerodynamic braking of the machines. Mechanical braking will need to be transitioned into a new design that allows the vertical rotors to brake more quickly, like the traditional horizontal axis wind machines do. This will keep Sandia engineers busy.

The first phase of the program will take place over two years and will involve creating several concept designs, running those designs through modern modeling software and narrowing those design options down to a single, most-workable design. In phase two researchers will build the chosen design over three years, eventually testing it against the extreme conditions that a turbine must endure in an offshore environment.

Editor’s Deep Dive

- https://share.sandia.gov/news/

resources/news_releases/vawts/ - http://www.redorbit.com/news/

science/1112666939/vertical- wind-turbine-offshore-power/ - http://social.

windenergyupdate.com/offshore- wind/vertical-axis-wind- turbines-only-way - http://en.wikipedia.org/wiki/

Wind_turbine

Thomas Edison said … “I always invented to obtain money to go on inventing.”

Thomas Edison said … “I always invented to obtain money to go on inventing.”

Time® is a registered trademark of Time Inc.